Patented foldable and portable system

Increased portability, independent of location

| Length | 123 1/2 inch (folded 29 1/4 inch) |

| Width | 70 1/2 inch |

| Height | 32 inch (folded 75 3/4 inch) |

| Maximum cutting width | 54 inch |

| Maximum cutting length | 86 1/2 inch (with extension 139 1/4 inch) |

| Maximum cutting depth | 2 7/16 inch |

| Length | 3132 mm (folded 744 mm) |

| Width | 1790 mm |

| Height | 810 mm (folded 1925 mm) |

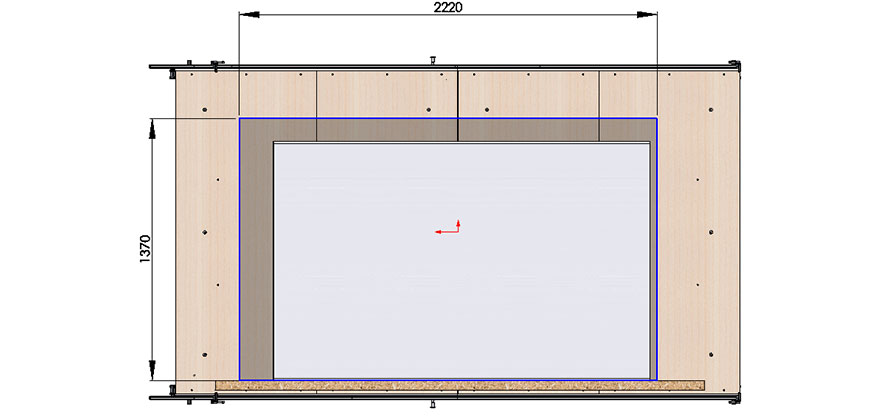

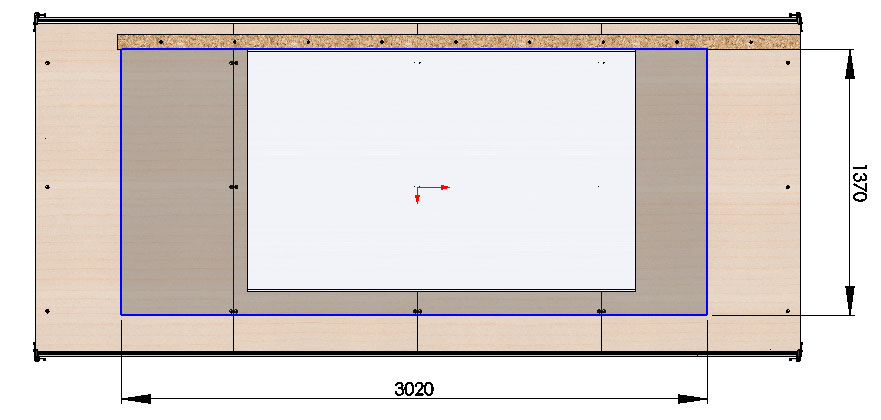

| Maximum cutting width | 1370 mm |

| Maximum cutting length | 2200 mm (with extension 3537 mm) |

| Maximum cutting depth | 62 mm |

Standard system in two different lengths

Increased stability, extended processing surface

| Length | 156 inch / 189 inch |

| Width | 70 1/2 inch |

| Height | 31 inch |

| Maximum cutting width | 54 inch |

| Maximum cutting length | 147 1/4 inch (with extension 210 inch) |

| Maximum cutting depth | 2 7/16 inch |

| Length | 3960 mm / 4800 mm |

| Width | 1790 mm |

| Height | 790 mm |

| Maximum cutting width | 1370 mm |

| Maximum cutting length | 3742 mm (with extension 5335 mm) |

| Maximum cutting depth | 62 mm |

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

1020 Winding Creek Road

Suite #120

Roseville, California 95678

USA

© flextos GmbH. All Rights Reserved. All content, ideas, concepts and products are protected by copyright.