Most effective production processes

High tech in drywall construction

Fast return of investment

Most effective production processes

High tech in drywall construction

Fast return of investment

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

| Length | 198 1/2 inch |

| Width | 70 1/2 inch |

| Height | 31 inch |

| Length | 41 1/2 inch |

| Width | 13 1/4 inch |

| Height | 51 1/4 inch |

| Table | 514 lbs |

| Gantry | 298 lbs |

| Control cabinet | 287 lbs |

Step motors

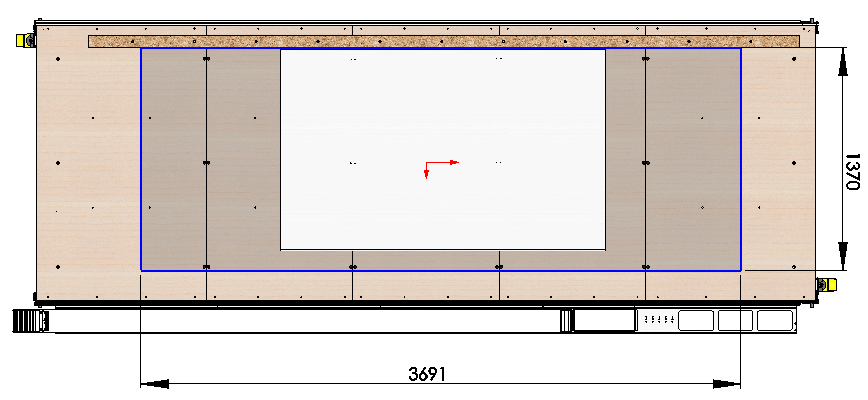

| Length | 5040 mm |

| Width | 1790 mm |

| Height | 790 mm |

| Length | 1053 mm |

| Width | 350 mm |

| Height | 1300 mm |

| Table | 233 kg |

| Gantry | 135 kg |

| Control cabinet | 130 kg |

Step motors

1020 Winding Creek Road

Suite #120

Roseville, California 95678

USA

© flextos GmbH. All Rights Reserved. All content, ideas, concepts and products are protected by copyright.