Flexible to use

Ideal for drywall construction and exhibition contractors

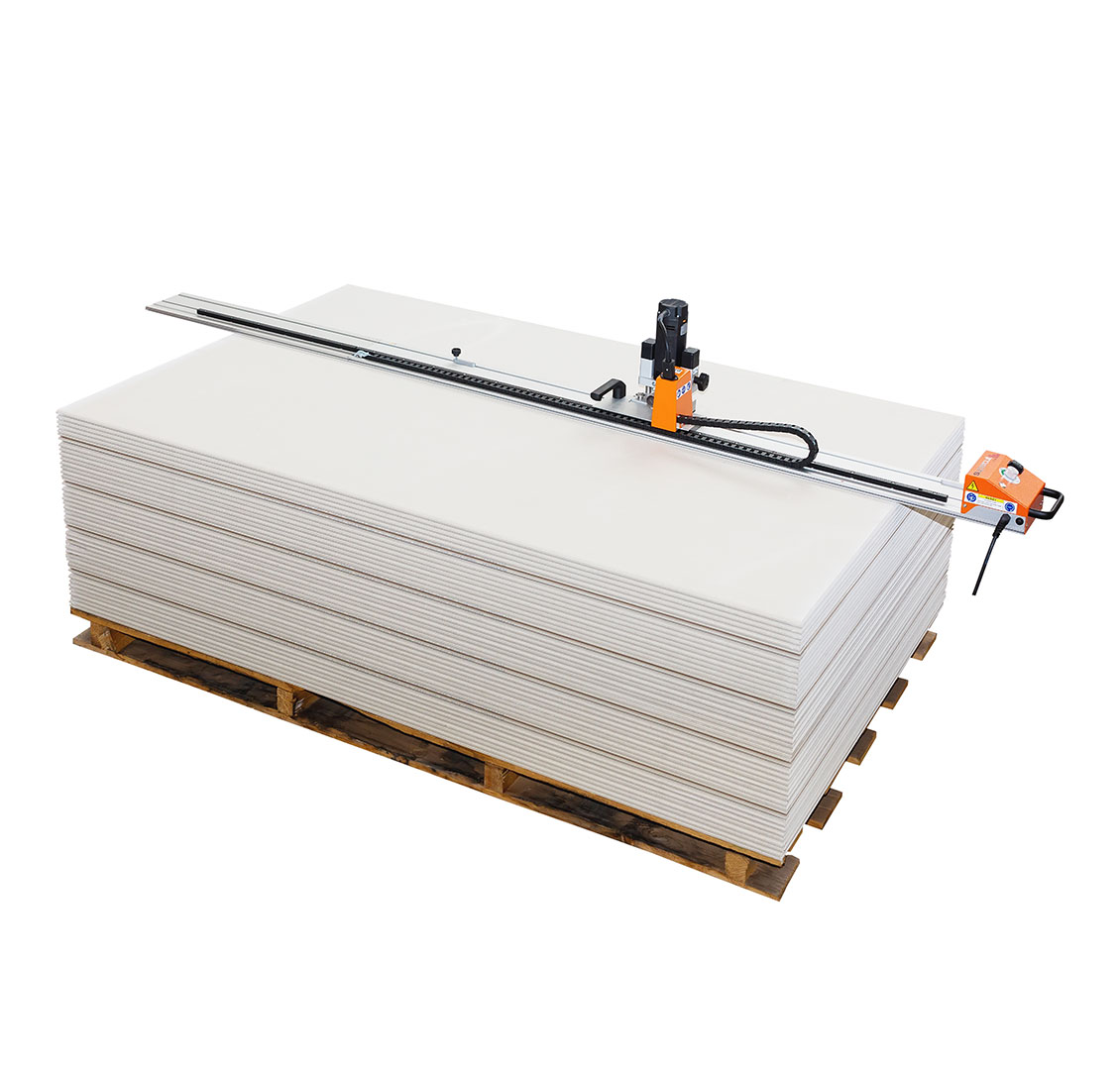

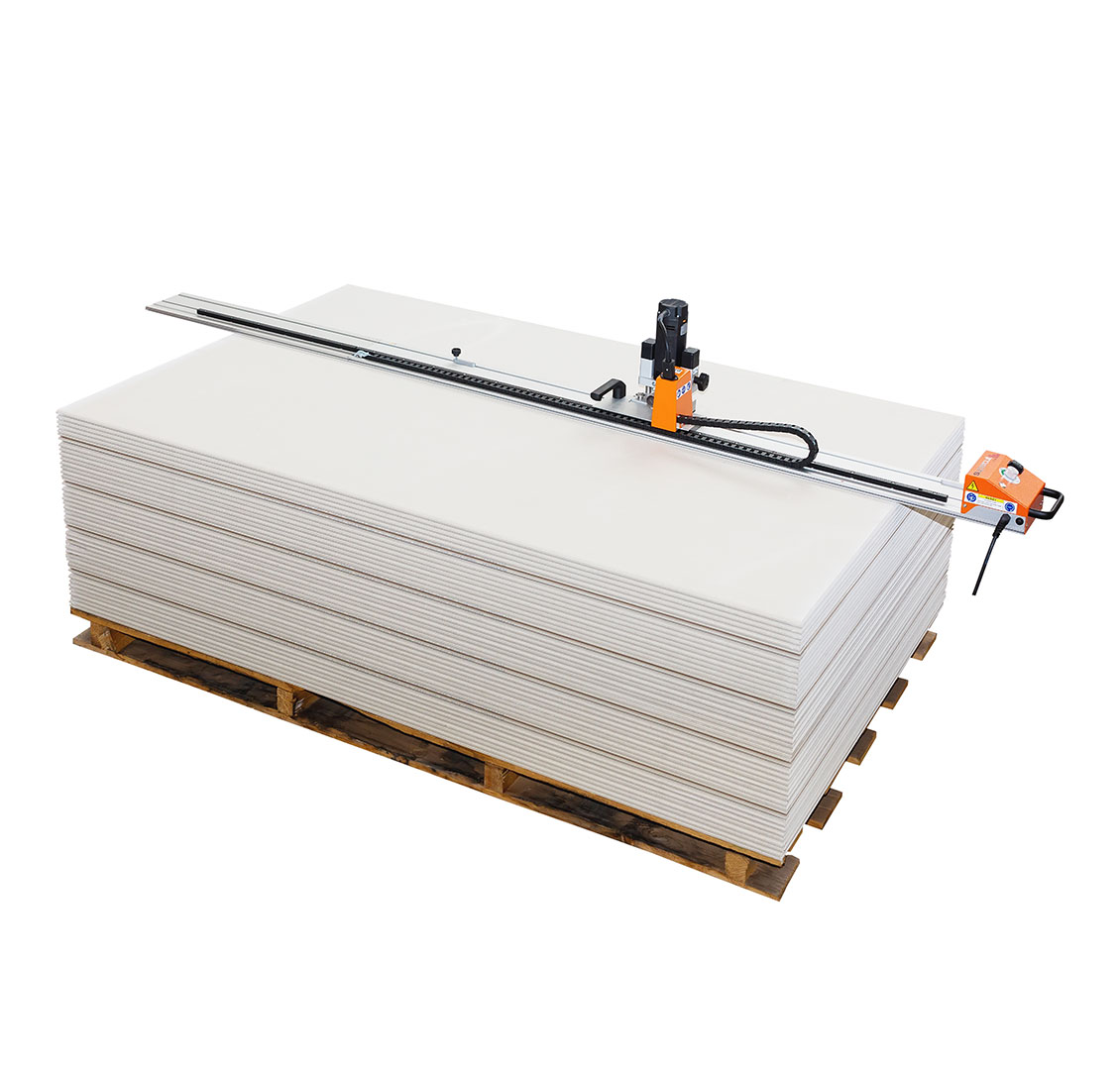

Processing directly on the pallet

Flexible to use

Ideal for drywall construction and exhibition contractors

Processing directly on the pallet

By loading the video, you accept YouTube's privacy policy.

Learn more

| Length | 57 inch |

| Width | 9 5/8 inch |

| Height | 9 1/2 inch |

| Weight | 24.25 lbs |

| Maximum cutting length | 100 3/8 inch = 8 1/2 ft (with extension rails) |

| Maximum cutting depth | 1 5/8 inch |

23 5/8 inch and 55 1/8 inch

Step motors

| Length | 1450 mm |

| Width | 245 mm |

| Height | 241 mm |

| Weight | 11 kg |

| Maximum cutting length | 2550 mm (with extension rail) |

| Maximum cutting depth | 42 mm |

1400 mm and 600 mm

Step motors

1020 Winding Creek Road

Suite #120

Roseville, California 95678

USA

© flextos GmbH. All Rights Reserved. All content, ideas, concepts and products are protected by copyright.