Most effective production processes

High tech in drywall construction

Fast return of investment

Most effective production processes

High tech in drywall construction

Fast return of investment

By loading the video, you accept YouTube's privacy policy.

Learn more

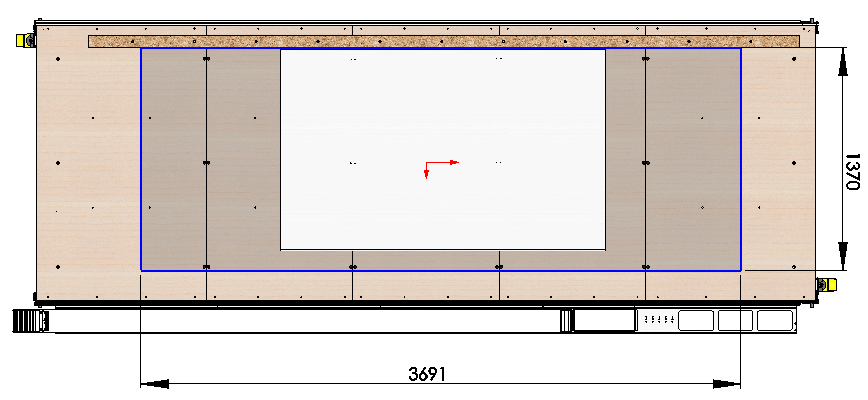

| Length | 198 1/2 inch |

| Width | 70 1/2 inch |

| Height | 31 inch |

| Length | 41 1/2 inch |

| Width | 13 1/4 inch |

| Height | 51 1/4 inch |

| Table | 514 lbs |

| Gantry | 298 lbs |

| Control cabinet | 287 lbs |

Step motors

| Length | 5040 mm |

| Width | 1790 mm |

| Height | 790 mm |

| Length | 1053 mm |

| Width | 350 mm |

| Height | 1300 mm |

| Table | 233 kg |

| Gantry | 135 kg |

| Control cabinet | 130 kg |

Step motors

1020 Winding Creek Road

Suite #120

Roseville, California 95678

USA

© flextos GmbH. All Rights Reserved. All content, ideas, concepts and products are protected by copyright.