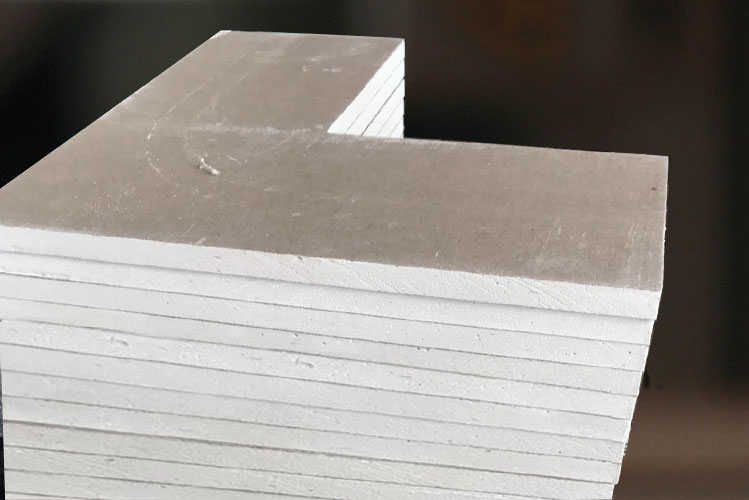

Portable milling and sawing system for simple and fast processing for on-site construction. Moulded parts can be produced directly from the plasterboard pallet.

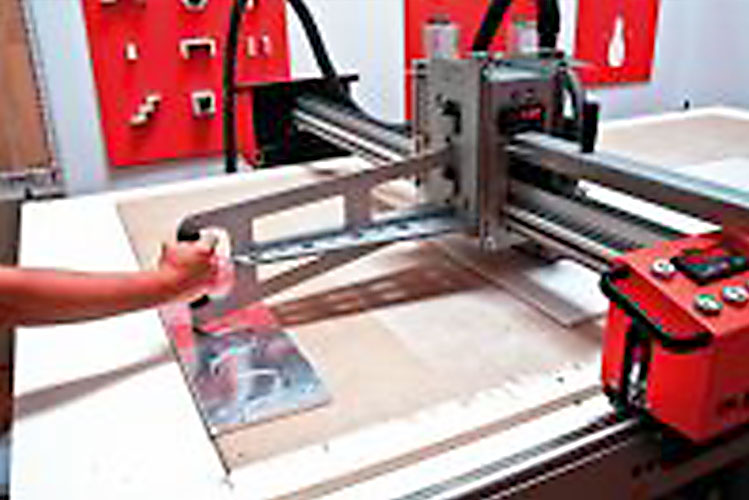

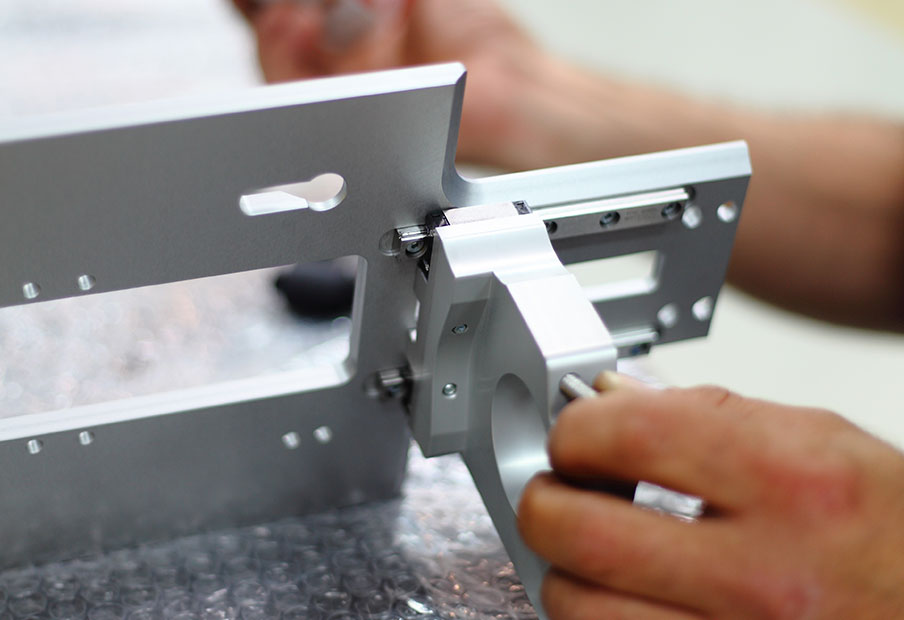

Semi-stationary milling and sawing system; consisting of a gantry with modularly interchangeable tools and a portable and foldable table.

The milling and sawing unit (gantry) corresponds to that of the XPK, but the XPS has a stationary and larger table with an extended processing surface.

High-tech milling and sawing system based on CNC, which facilitates the production of the most complex shapes and automates numerous production processes.

Optimise time, quality and costs in drywall construction while improving your production processes: Our professional milling and sawing systems are ideal for processing plasterboard panels and numerous other materials. The production of angular and round moulded parts is significantly simplified; corners and edges become child’s play. You will receive an all-round package together with our high-quality accessories and first-class service, allowing you to start immediately and be successful over the long term.

The high degree of prefabrication with the help of our products means that we support companies in the areas of lean production/construction!

For demanding drywall construction projects

Easy handling and operation

Convenient laser setting

Close to 100 % dust extraction

Processing of different sheet materials

XPM |

XPK |

XPS |

CNC |

|

| Milling | ✓ | ✓ | ✓ | ✓ |

| Sawing up to a cutting depth of 42 mm | ✓ | |||

| Sawing up to a cutting depth of 62 mm | ✓ | ✓ | ✓ | |

| Making cutouts | ✓ | ✓ | ✓ | |

| Processing of various panel materials | ✓ | ✓ | ✓ | ✓ |

| One-man operation | ✓ | ✓ | ✓ | ✓ |

| Production of blanks | ✓ | ✓ | ✓ | ✓ |

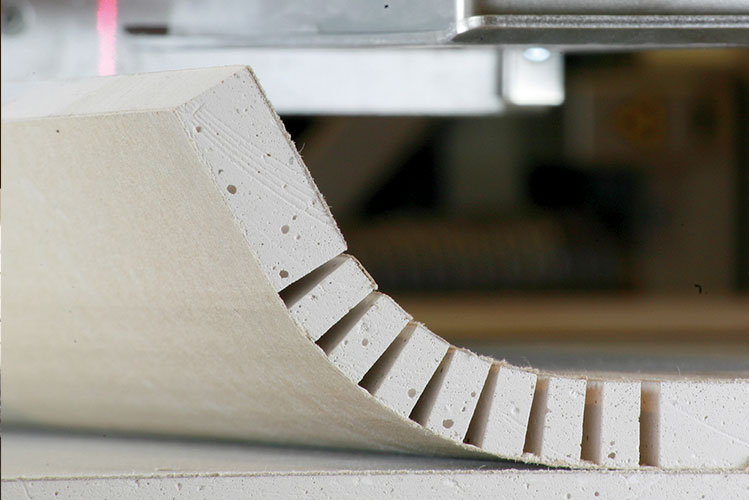

| Production of shaped parts | ✓ | ✓ | ✓ | ✓ |

| … in medium to high quantities | ✓ | ✓ | ✓ | |

| Production of complex molded parts | ✓ | ✓ | ✓ | |

| Realization of high quality and design requirements | ✓ | ✓ | ✓ | |

| Copy milling | ✓ | ✓ | ||

| Use of flush milling cutters | ✓ | ✓ | ||

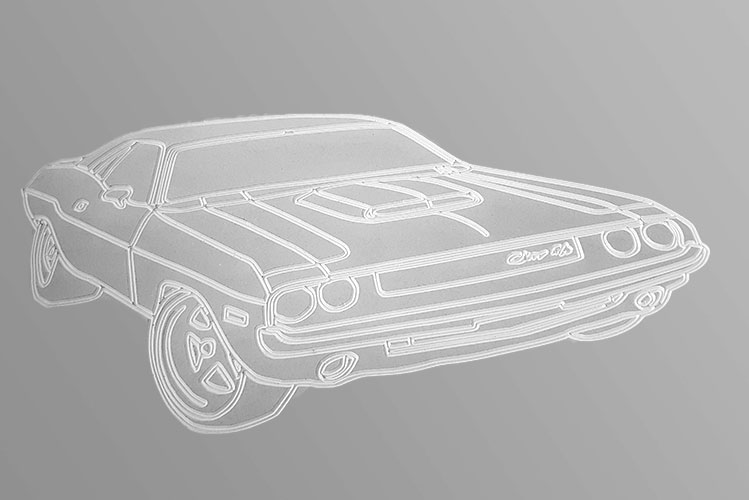

| Production of engravings | ✓ | |||

| Effective one-man operation (parallel work possible through automation) | ✓ | |||

| Automatic milling of logos and shapes | ✓ | |||

| Production of free-form shapes across plates | ✓ | |||

| Choice of versatile design options | ✓ |

XPM |

XPK |

XPS |

CNC |

|

| Simplified production processes | ✓ | ✓ | ✓ | ✓ |

| Flow-optimized extraction (cyclone separator) | ✓ | ✓ | ✓ | ✓ |

| Convenient laser adjustment | ✓ | ✓ | ✓ | ✓ |

| Powerful motors | ✓ | ✓ | ✓ | ✓ |

| Table extension modules | ✓ | ✓ | ✓ | ✓ |

| Milling and sawing without changing aggregates | ✓ | ✓ | ✓ | |

| Self-driving, exchangeable aggregates | ✓ | ✓ | ||

| Replaceable units | ✓ | ✓ | ✓ | ✓ |

| Manual suction to the used aggregate | ✓ | |||

| Automatic suction and suction switching | ✓ | ✓ | ✓ | |

| Automatic aggregate lifting unit | ✓ | ✓ | ✓ | |

| Digital measuring system in all axes | ✓ | ✓ | ✓ | |

| Increased mobility | ✓ | ✓ | ||

| Magnetic clamping in both axes | ✓ | ✓ | ||

| Automated production processes | ✓ | |||

| CNC code import | ✓ | |||

| Teach-in function | ✓ | |||

| Preset programs without additional programming effort | ✓ |

XPM |

XPK |

XPS |

CNC |

|

| Savings in time, personnel and costs (up to 75 %) | ✓ | ✓ | ✓ | |

| Ease of use | ✓ | ✓ | ✓ | ✓ |

| Flexibility or independence from suppliers | ✓ | ✓ | ✓ | ✓ |

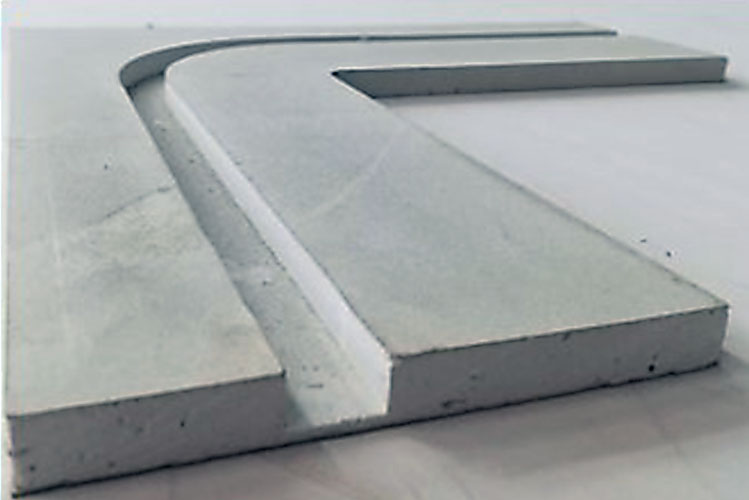

| Transport and assembly of the molded parts in one piece | ✓ | ✓ | ✓ | ✓ |

| No profiles and filler work necessary | ✓ | ✓ | ✓ | ✓ |

| Virtually dust-free working | ✓ | ✓ | ✓ | ✓ |

| High molded part stability and impact resistance | ✓ | ✓ | ✓ | ✓ |

| Fast and cost-effective production of molded parts | ✓ | ✓ | ✓ | ✓ |

| Location-independent working | ✓ | ✓ | ||

| Production of three-dimensional molds | ✓ | ✓ | ✓ | ✓ |

| Simple production of complex molded parts | ✓ | ✓ | ✓ | |

| Consistent high quality of molded parts | ✓ | ✓ | ✓ | ✓ |

| Production of large quantities of standard molded parts | ✓ | ✓ | ✓ | |

| Production of round and curved molded parts | ✓ | |||

| Parallel work possible through automation | ✓ | |||

| Standardization and digitization | ✓ |

Our matching supplementary products make our system complete, allowing you to work perfectly and seamlessly.

Table and rail extensions make it possible to increase the processing surface area with the simplest of means

We offer various versions of milling and sawing motors for specialised applications

Milling cutters, saw blades, copying modules, circular cutters, etc. complete the SUPERCUT systems

High-performance vacuum systems and cyclone separator enable a virtually dust-free work environment

High-pressure glue guns and professional adhesive materials optimally bonding panels together

We will soon be publishing our online accessories shop. Until then, we will be pleased to advise you by e-mail or telephone and send you further information.

Engraving cutters

Ornamental milling

Multiple cuts

7-fold saw cuts

Copy milling machines

Milling cut-outs

Circle/circular milling

Cutting millers

Blanks

Perfect edges without needing grinding and filling → therefore no corner protection strip is necessary

Virtually dust-free work environment

Uniform, highest possible processing quality

Personnel, time and material savings

Flexibility and independence from suppliers

Quick operational readiness

We would be happy to work with you defining which of our systems is the right fit to meet your needs. We also provide support when it comes to financing, leasing, renting, funding, etc. and will be happy to prepare a customised offer for you.

We would be happy to work with you defining which of our systems is the right fit to meet your needs. We also provide support when it comes to financing, leasing, renting, funding, etc. and will be happy to prepare a customised offer for you.

1020 Winding Creek Road

Suite #120

Roseville, California 95678

USA

© flextos GmbH. All Rights Reserved. All content, ideas, concepts and products are protected by copyright.