Do you want to take your drywall offering to the next level? Save time? And get more money?

Panel processing in no time – Custom-shaped parts at the touch of a button.

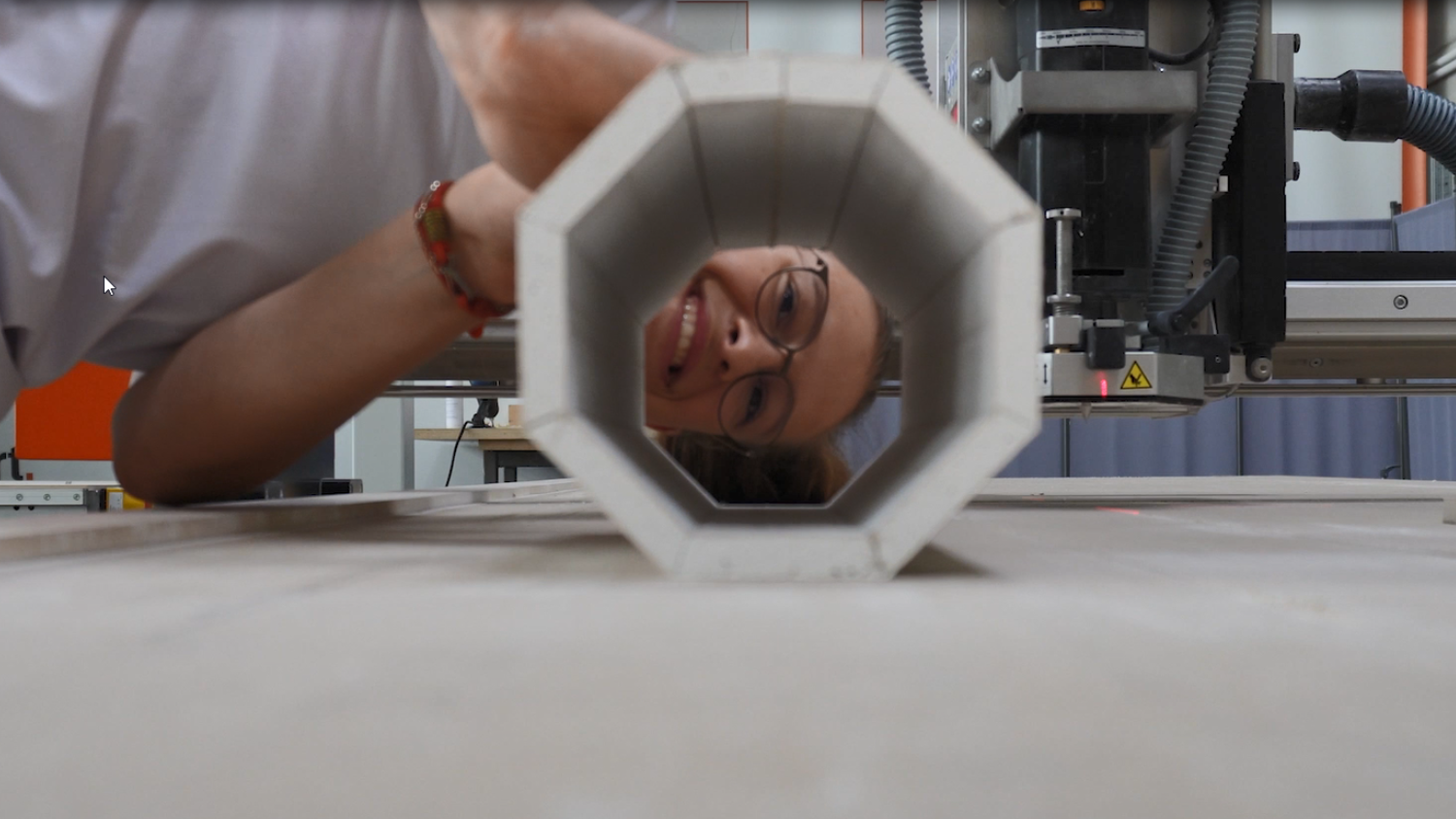

All of this is possible with the SUPERCUT milling and sawing tables from flextos.

Originally developed for drywall and gypsum board processing, the SUPERCUT tables can now handle countless types of panel materials (and we probably forgot a few…):

- Alucobond

- Aluminum composite panels

- Aquapanels

- Building panels

- Fire-resistant panels

- Eternit panels

- Fiber composite panels

- Facade panels

- Tongue and groove pressed wood particle boards

- Fermacell boards

- Fireboards

- Formwork panels

- Wood fiber panels

- Wood panels

- Wood composite panels

- Insulation panels

- Insulating materials

- Calcium silicate boards

- Kitchen panels

- Laminate panels

- Perforated panels

- Solid panels

- MDF (Medium Density

- Fiberboard) panels

- Multi-layer panels

- OSB (Oriented Strand Board) panels

- Parquet

- PU foam panels

- Formwork panels

- Dry subfloors

Work quickly, easily, and precisely

Whatever you want or need to build – it’s done quickly and easily with a flextos SUPERCUT! See it for yourself – at our showroom in Raubling near Rosenheim (in the work-smart Center) or during a live demonstration at your location (with the work-smart Truck).

If interested, simply send an email to: info@flextos.com

From mobile to automated

available for every hall size

You have the choice: From the mobile machine SUPERCUT XPM for the GKB (gypsum plasterboard) range, to the folding table SUPERCUT XPK, and up to the stationary machines SUPERCUT XPS in various sizes. And for those who prefer automation, we recommend the SUPERCUT CNC. Save the program – and with a click, you’ll receive as many precisely identical custom-shaped parts, millings, cutouts, engravings, etc. as you desire.

The advantages are clear:

- You save time – and produce quickly and precisely without laborious and error-prone manual production steps.

- You save money – labor costs and waste are minimized, self-produced prefabricated custom-shaped parts are much cheaper than purchased parts.

- You work at a consistently high level – with the SUPERCUT tables, millings, cuts, and custom-shaped parts are always precisely the same, without manual deviations.

- You expand your offering – there are no limits to your imagination. Custom-shaped parts of all kinds are quickly produced, cutouts are prepared in advance.

This makes you much faster on the construction site and work even more professionally.

Sounds good?

It is! And we’d be happy to show you.

Simply make an appointment, and we’ll come over:

Phone: +49 8031 23388-60